Glycol Chillers Designed for Breweries & Distilleries

Maximize Beer Production and Cool Fermentation Tanks, Brite Tanks and Wort Coolers.

- High fluid flow promotes maximum heat transfer for faster and more consistent product cooling.

- Designed to Provide 20°F - 30°F Glycol - to support all of your cooling needs.

- Built for your environment - rugged design shrinks your worries, reduces maintenance cost and provides the best product for your needs.

- Backed by a nationwide service network of independent service companies that accelerates service attention and minimizes downtime in the event of a problem.

- Backed by experienced application and service professionals. Our applications specialists listen to your unique requirements to guarantee the selection of the correct glycol/water chiller to meet your needs while minimizing your initial investment and ongoing energy costs.

- Have A Question? Looking For Help? Not sure what you need in a glycol chiller for your brewery? Call Advantage at 317-887-0729

Partial List of Brewing Customers OpenClose

- El Paso Brewing Company, El Paso, Texas

- Flat 12 Brierwerks, Indianapolis IN

- O'so Brewing Co, Plovel, Wisconsin

- Deadly Sins Brewing, Winter Park, Florida

- Peak 54 Brewing, Corona, CA

- Une Annee, Chicago, Illinois

- Great Spirits, Boulder, Colorado

- Hopfusion Ale Works, Fort Worth, Texas

- Parched Eagle Brewpub, Westport WI

- Needy Craft, Indianapolis, Indiana

- Chippewa River Distillery, Chippewa Falls, Wisconsin

- Woodland Beer, Marcy, New York

- Restless Spirits Distilling, North Kansas City, Missouri

- St Joseph Brewery & Public House, Indianapolis IN

- Deer Creek Brewery, Noblesville, IN

- Jughandle Brewing Company, Tinton Falls, New Jersey

- Elevation 5003 Distillery, Fort Collins, Colorado

- Euryale Brewing, Riverside CA

- Humble Abbey Brewing, Lake Clarke Shorts, Florida

- Parched Eagle Brewpub, Westport, Wisconsin

- Reverence Brewing Company,

- Pivot Brewing Company, Central Valley, New York

- Demented Brewing Co, Middlesex NJ

- Hopkinsville Brewing, Hopkinsville, Kentucky

- Shale Creek Brewery, Franklin, Indiana

- Bent Rail Brewery, Indianapolis, Indiana

- Sierra Nevada Brewing, Chico, California

- Hoi Polloi Brewpub, Berkeley, California

- Railhouse Brewery, Aberdeen NC

- Brookeville Brewing, Brookeville, Maryland

- Great Barn Brewery, Kintnersville, PA

- August Schell Brewing Co., New Ulm, MN

- Flying Heart Brewing, Bossier City, Louisiana

- The Commons Brewery, Portland OR

- Grand Junction Brewing, Westfield IN

- Cedar Creek Brew company, Seven Points, Texas

- Ash & Elm Cider, Indianapolis, IN

- Friendship Brewing Company, Wentzville, Missouri

- Chambers Bay Distillery LLC, University Place, Washington

- Winchester Brew Works, Winchester, VA

- Dockside 700, Tahoe City CA

- Black Mountain Distillery, Cave Creek, Arizona

- Absolute Threshold Brewery, Fort Collins, CO

- Obed and Isaacs, Springfield, Illinois

- Delta Blues Winery, Lackland, Tennessee

- Three Rings Brewery, McPherson, Kansas

- Lake Charlevoix Brewing, Charlevoix MI

- Four Day Ray Brewing, Fishers, Indiana

- Stone Church Brewing, Corona, CA

- Sun King Brewing, Indianapolis IN

- Bluetick Brewery, Maryville TN

- LaOtta Brewing, LaOtta, Indiana

- Round Town Brewery, Indianapolis, IN

- Four Bullets Brewery, Richardson TX

- Black Cloister Brewing Co, Toledo OH

- Red Dragon Brewery, Fredericksburg, Virginia

- Wayfarers Ale Ltd, Port Williams, NS

- Knuth Brewing, Ripon, Wisconsin

- Mount Pleasant Brewing Co, Mt Pleasant MI

- Cotton and Reed, Washington DC

- Black Swan Brewpub, Plainfield IN

- Five Points Brewing Co, San Deigo CA

- French Lick Winery, West Baden Springs, Indiana

- 1859 Cider Company, Salem, Oregon

- Ocean Son, Orlando, Florida

- Millersburg Brewing Company, Millersburg, Ohio

- Hoosier Brewing Company, Franklin, Indiana

- Clam Lake Beer Company, Cadillac MI

- Dry County Brewing, Spruce Pine, North Carolina

- Weyerbacher Brewing Co, Easton PA

Need Help Choosing A Glycol Chiller For Your Brewery?

Click Here for the Free Glycol Chiller Selection Tool

Resources

Details on how to prepare your facility for the arrival of your glycol chiller.

Download

Type: Booklet

Pages: 10

Size: 1.6 MB

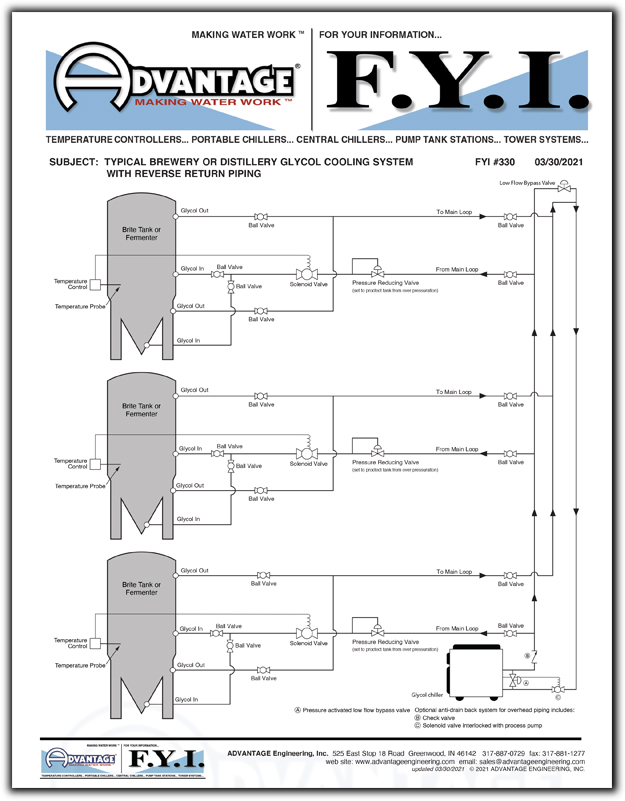

Typical Brewery or Distillery Glycol Cooling System With Reverse Return Piping

Download

Type: Drawing

Pages: 1

Size: 523 KB

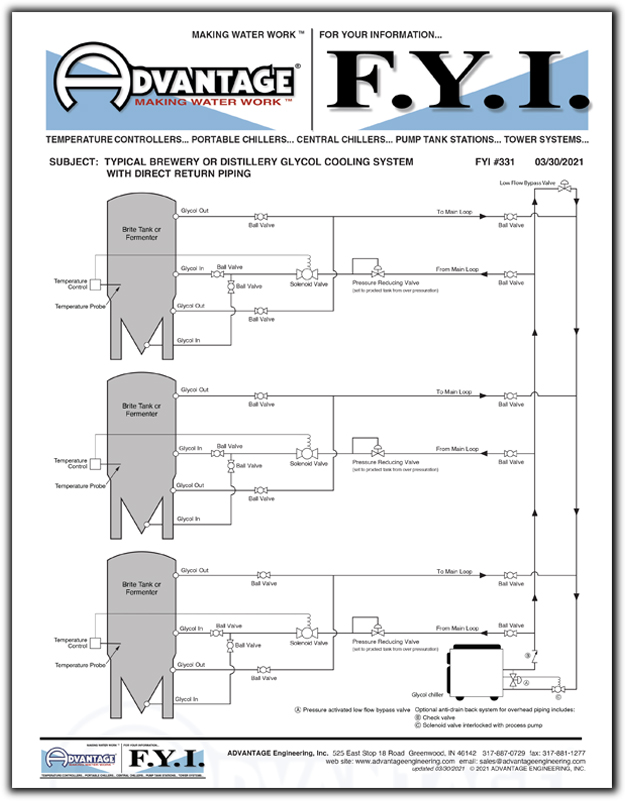

Typical Brewery or Distillery Glycol Cooling System With Direct Return Piping

Download

Type: Drawing

Pages: 1

Size: 524 KB

Indoor Units

Model

Capacity BTU *

Compressor Horsepower

Pump Horsepower

Flow GPM

*Capacity at 25°F LFT and 115°F condensing temperature. Capacities may be +/5% as reserved by the compressor manufacturer. The minimum recommended operating temperature when no glycol is used is 48°F.

Outdoor Units

Model

Capacity BTU *

Compressor Horsepower

Pump Horsepower

Flow GPM

*Capacity at 25°F LFT and 115°F condensing temperature. Capacities may be +/5% as reserved by the compressor manufacturer. The minimum recommended operating temperature when no glycol is used is 48°F.

Disclaimer: Advantage has made every effort to ensure that the results generated by the calculators available at this website are correct and valid within the limitations indicated for each calculator. However, neither Advantage nor any of its employees warrants nor accepts any liability for the use of these calculators. Use of these calculators and selection of specific input parameters often requires engineering judgment on a case by case basis. The user is cautioned to seek competent engineering assistance in the use of the calculators and application of results generated by the calculators. The user is further cautioned that the results generated are based upon certain simplifying assumptions, which may or may not be valid for a specific case.

Need Application Assistance?

Our Experienced Team Can Save You Time & Money.

Tell Us About Your Project