To see IMMEDIATE online pricing, please complete the form below for the M1D-5A-RC

Pricing will be displayed on our website when you fill out the form below and click Get Pricing Now.

- Get Pricing Now

- Your privacy is assured, of course. Your information will be used by Advantage and its representatives only. It will not be provided or sold to others. It will be used for purposes of this inquiry only.

- Home

- > Products

- > Portable Chillers

- > Water Chillers with Remote Condensers

- > M1D-5A-RC

Water Chiller with Remote Condenser : 5 Tons

Model: M1D-5A-RC

- Overview

- Specifications

- Features

- Options

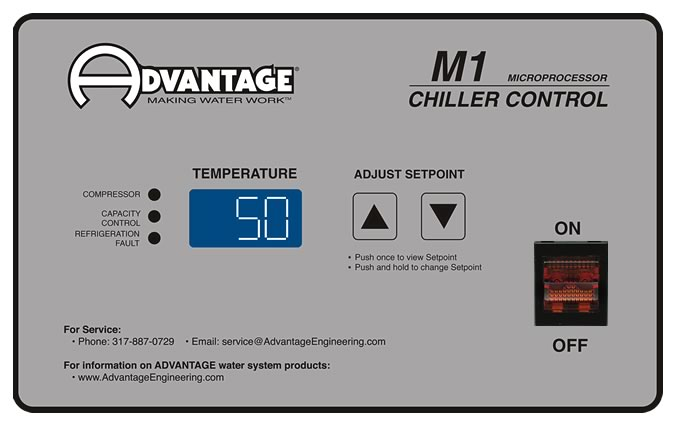

- Control Instrument

- Support Documents

- Photo Here

M1D-5A-RC

Image is typical. Actual unit appearance will vary according to specifications and options.

-

Need Application Assistance?

Our Experienced Team Can Save You Time & Money.

Tell Us About Your Project