- 877-290-1853

Search

To see IMMEDIATE online pricing, please complete the form below for the M1-2W

Pricing will be displayed on our website when you fill out the form below and click Get Pricing Now.

This legacy model is no longer in production. The equivalent model is the

MG-2W.

Water-Cooled Portable Water Chiller

Model: M1-2W

- Portable chillers use mechanical refrigeration to cool recirculated fluids that support industrial process cooling applications.

- Portable chillers include an internal pumping system and reservoir system.

- Portable chillers can be moved between use points as needed.

- Water-Cooled chillers use plant water supplies to dissipate the heat from the refrigeration system.

M1-2W- Unit Cooling Capacity

- (2) Tons : 2

- kW : 7.0

- Compressor

- HP : 2

- Type : Scroll

- Process Pump

- HP : 3/4

- GPM : 4.8

- PSI : 32

- Type : Centrifugal

- Construction : Stainless Steel

- Water-Cooled Condenser

- (3) City : 3 gpm

- (4) Tower : 6 gpm

- Refrigerant

- Type : R-410A

- Full Load Amperage (5)

- 230/3/60 : 16

- 460/3/60 : 8

- 575/3/60 : 7

- Reservoir Capacity

- Holding : 7.5 gal

- Lid : Optional

- Auto Make-Up : Optonal

- Dimensions

- Height : 30"

- Width : 37"

- Depth : 24"

- Process Connections

- To Process : 3/4"

- From Process : 3/4"

- Condenser : 1/2"

- Make-Up : 1/2"

- Weight

- Shipping : 445 lbs

- Specification Notes:

- 1. Since product innovation and improvement is our constant goal, all features and specifications are subject to change without notice or liability. Selection of certain optional features may change listed specifications.

- 2. Tons capacity at 12,000 BTU/ton per hour @ 50°F LWT @ " 105"°F condensing temperature. Capacities may be +/- 5% as reserved by the compressor manufacturer. Operating at temperatures below 50° will reduce chiller capacity. The minimum recommended operating temperature when no glycol is used is 48°F.

- 3. City water requirements based on 60°F water supply at 20 PSI differential with a clean condenser.

- 4. Tower water requirements based on 85°F water supply at 20 PSI differential with a clean condenser.

- 5. Full load amps are higher than run load amps and must be used for sizing disconnects and supply wiring.

- 6. Approximate unit weight crated for shipment.

- Refrigerant Circuit:

- R410A refrigerant

- Non-Ozone depleting

- Low global warming impact - Scroll Compressor

- Tube-In-Tube water-cooled condenser with regulator valve

- Brazed plate evaporator

- Stainless steel plates

- Copper brazing material - Hot gas bypass down to 50% capacity

- Referant sight glass with moisture indicator

- Filter-drier

- Thermostatic expansion valve

- Liquid line solenoid valve

- Electrical:

- Nema 1 control cabinet

- Process pump motor starter

- Compressor contactor

- Power entry terminal block

- Branch Circuit Fusing

- Pressure Gauges:

- Refrigerant high pressure

- Refrigerant low pressure

- Coolant pressure

- Coolant Circuit:

- High flow centrifugal pump

- Insulated non-ferrous reservoir

(tank lid is standard on this model) - Reservoir level sight glass

- Standard NPT process fittings

- System Limit Devices:

- High refrigerant pressure

- Low refrigerant pressure

- Process pump motor overload

- Frame Construction:

- Stainless steel sheet metal

- Lift-off top cover panel

- Lift-off side panels

- Castors - for portability

- Designed for indoor installation

- Electrical

- UL 508A Enclosed Electrical Panel

- Coolant Circuit

- Overhead Piping Kit

- Reverse Flow ... no reservoir tank for gravity return applications

- Automatic Low Flow Bypass

- Process Line Shut Off Valves

- Larger Process Pumps

- Warranty

- Extended Compressor Warranty

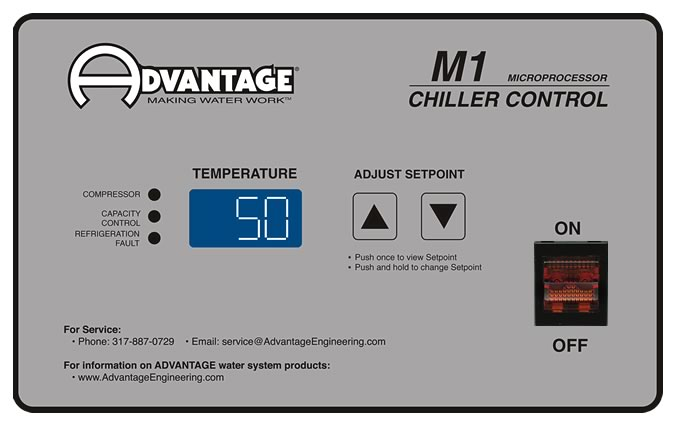

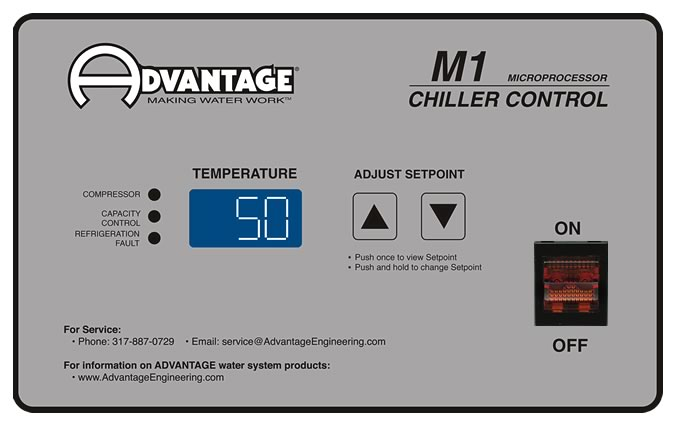

M1 Series

(standard instrument)- Continuous To Process temperature display

- Selectable Setpoint temperature display

- Illuminated ON/OFF power switch

- Soft touch Setpoint selection keys

- Illuminated Chiller On / Off switch

- Bright and easy-to-read LED Temperature display window

- Basic chiller diagnostics with Refrigeration Fault light

- Machine Status with Compressor and Capacity Control indicating lights

- Basic Machine Diagnostics with Refrigeration Fault indicating light

M1-2W

Image is typical. Actual unit appearance will vary according to specifications and options.

-

Need Application Assistance?

Our Experienced Team Can Save You Time & Money.

Tell Us About Your Project

Close

This site uses cookies to offer you a better browsing experience. Learn more about how Advantage Engineering, Inc. uses cookies by contacting the site

administrator at admin@advantageengineering.com By closing this banner, scrolling this page, clicking a link or continuing to browse otherwise, you agree to the use of cookies.

Please refer to the Advantage Engineering Privacy Policy.