Many heating, air conditioning, and ventilation (HVAC) users prefer a closed hydronic water circulation system to Advantage Engineering's typical open reservoir style system.

Applying this style system in an industrial process application requires careful consideration and thorough pre-planning before selecting the system components and installing the system.

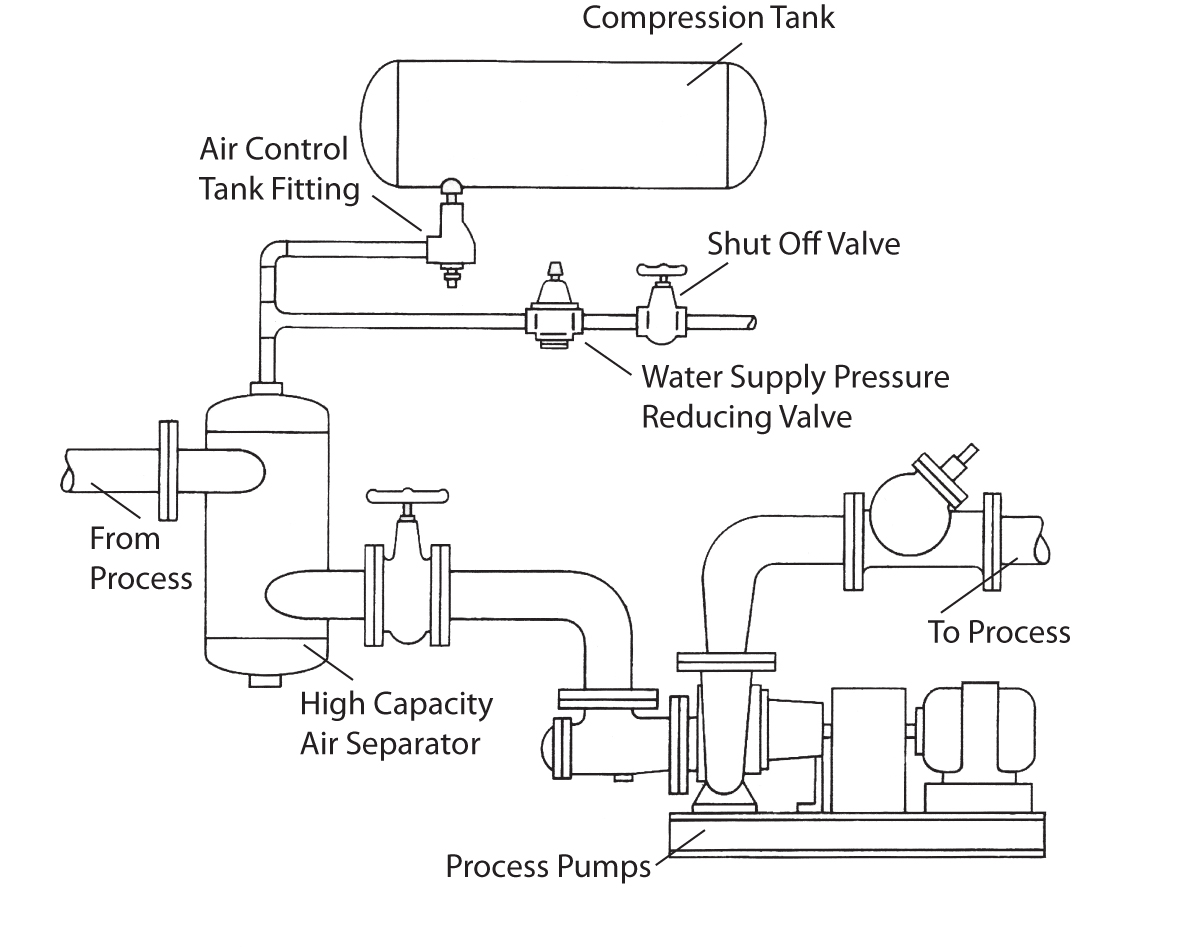

Typical components of a hydronic system include:

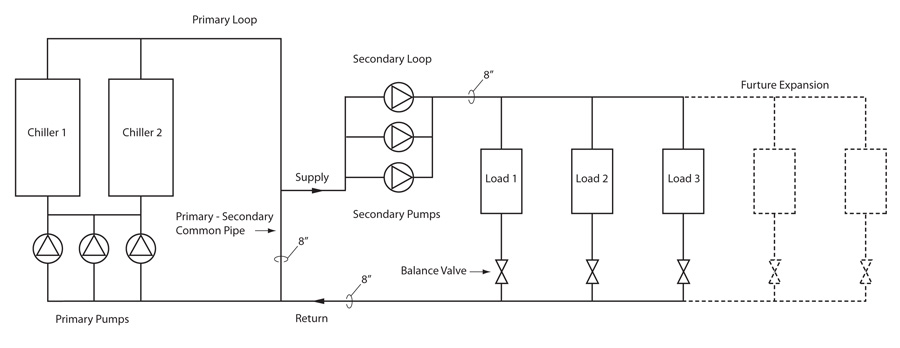

The schematic below illustrates a a typical hydronic system.

Considerations for Closed Hydronic Systems.

This drawing is supplied to demonstrate a possible piping configuration. The drawing is general in nature and is not intended to be all inclusive of every detail that might be required for your specific location and installation. Advantage accepts no responsibility for piping and any other component supplied or installed by others.

For more information about hydronic system and primary-secondary pumping call the Advantage Sales Department at 317-887-0729.

Need Application Assistance?

Our Experienced Team Can Save You Time & Money.

Tell Us About Your Project