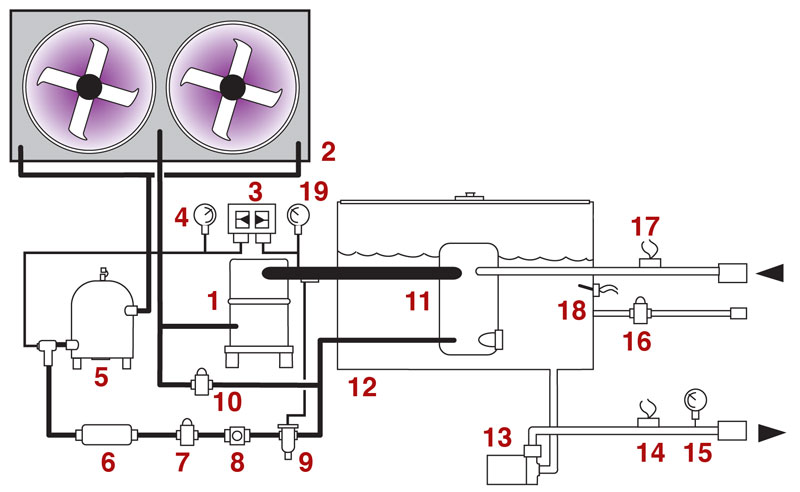

1

Compressor

The Compressor has two functions in the refrigerant cycle. First, it removes the refrigerant vapor from the evaporator and reduces the pressure in the evaporator to a point where the desired evaporating temperature can be maintained. Second, the compressor raises the pressure of the refrigerant vapor to a level high enough so that the temperature is higher than the temperature of the cooling medium available for condensing in the refrigerant vapor.

2

Air-Cooled Condenser

The condenser is a heat exchanger where the process heat absorbed by the refrigerant is given off to the air around it. As heat is given off by the high temperature high pressure vapor, its temperature falls until

the vapor condenses to a liquid. Motor driven fans generate airflow across the condenser.

3

Refrigerant Pressure Limit Switch

Protects the system against excessive pressure in the refrigerant circuit. For the most typical operations, the high pressure limit is factory set at 325# and the low pressure switch is set to open at 58# and close at 63#. Alteration of this limit switch is not advisable unless Factory directed.

4

High Refrigerant Pressure Gauge

Provides visual indication of the refrigerant condensing pressure.

5

Liquid Line Receiver Optional

The liquid receiver is a liquid storage tank for liquid refrigerant that is not in circulation. The receiver is required to hold the system refrigerant charge during service.

6

Filter Drier

The filter drier prevents or removes moisture, dirt, and other foreign materials from the refrigerant that will harm the system components and reduce efficiency.

7

Liquid Line Solenoid Optional

The liquid line solenoid is an electrically controlled refrigerant flow control valve that closes when the compressor stops. This prevents liquid refrigerant from migrating to the evaporator and causing liquid slugging when the compressor starts again. Liquid slugging can cause severe damage to the compressor. The valve is opened when the compressor is on.

8

Refrigerant Sight Glass

The refrigerant sight glass allows the operator or serviceman to observe the flow of liquid refrigerant. Adequate refrigerant is determined by a clear liquid flow. Bubbles indicate a shortage of refrigerant. The moisture indicator turns colors depending on the moisture content in the system. Green signals no moisture content, yellow signals that the system is contaminated with moisture and requires service.

9

Expansion Valve

The expansion valve meters the flow of liquid refrigerant into the evaporator at the proper rate to provide cooling of the process water As more cooling is required, additional refrigerant is metered through the valve into the evaporator.

10

Hot Gas Bypass Valve

The hot gas bypass valve prevents short cycling of the compressor by modulating the compressor capacity. When activated, the valve opens and allows hot refrigerant gas to enter the refrigerant stream entering the evaporator. This reduces the effective capacity of the system.

11

Evaporator

The evaporator is the device in which liquid refrigerant boils off, absorbing heat as it evaporates, cooling the process fluid.

12

Reservoir

The coolant reservoir provides adequate volume to support the flow requirements of the chiller. The reservoir is non-pressurized promoting air separation and high process flows.

13

Coolant Pump

The coolant pump circulates chilled fluid through the process loop.

14

To Process Sensor Probe

The to process sensor probe is placed in the coolant flow stream going to the process. Control decisions are made based on the TO PROCESS coolant temperature.

15

Coolant Pressure Gauge

Provides visual indication of the coolant pressure supplied to the process.

16

Water make Up Solenoid Valve Optional

When activated by the float switch, the WATER MAKE UP SOLENOID will open and introduce supply water to the reservoir. This restores the reservoir to the proper operating level.

17

From Process Sensor Probe

The from process sensor probe is placed in the coolant flow stream coming back from the process.

18

Reservoir Level float Switch Optional

The reservoir float level switch is place at the proper water level in the reservoir. If the water level falls below the proper level, the float switch activates the Water Make-Up Solenoid valve refilling the tank

to the proper level.

19

Low Refrigerant Pressure Gauge

Provides visual indication of the refrigerant evaporating pressure.