Selecting a pump for process flow is critical for effective heat transfer and for getting the most out of Advantage equipment.

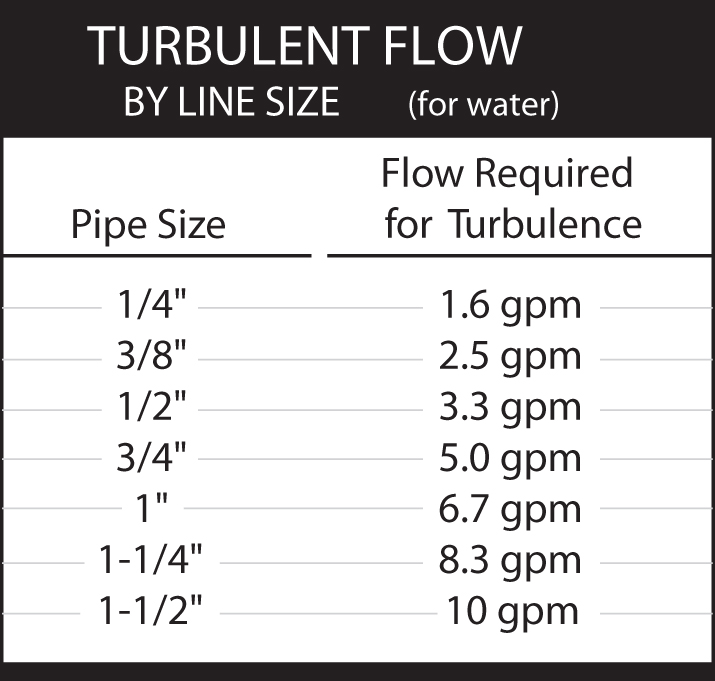

Example: a mold has ten (10) 3/8" ins/outs. To be turbulent, each 3/8" in/out should have 2.5 gpm. Therefore, 25 gpm is required. A 3/4 HP pump (like in an SK-1035LE) rated for 35 gpm is the correct machine for this application.

This chart can be used to help estimate the water flow rate required for a process in order to obtain turbulent flow conditions which promotes heat transfer.

For more information about Recommending and Selecting a Pump call the Advantage Sales Department at 317-887-0729.

Need Application Assistance?

Our Experienced Team Can Save You Time & Money.

Tell Us About Your Project