Copeland Scroll compressors are used on most Advantage portable and central water chillers, from 3 to 90 tons, air cooled and water cooled units.

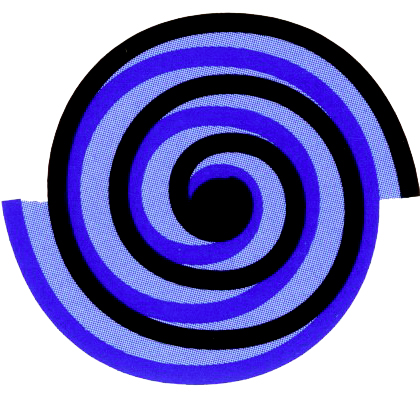

Operational sequence of Scroll Compressors

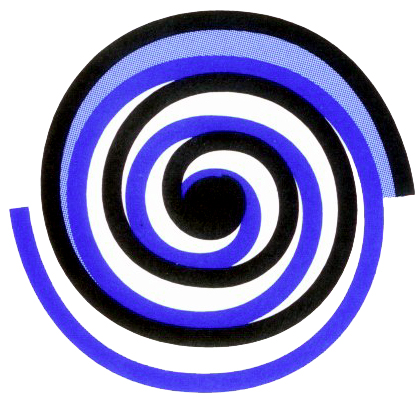

Step 1

Refrigerant enters outer opening as one scroll orbits the other.

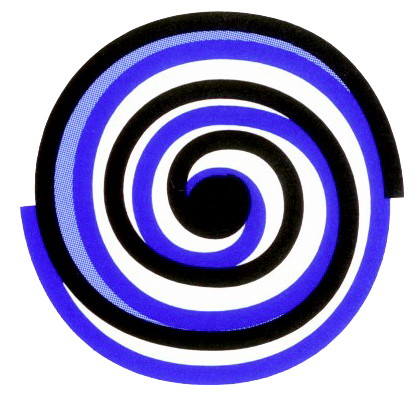

Step 2

The open passage is sealed and refrigerant is drawninto the compression chamber.

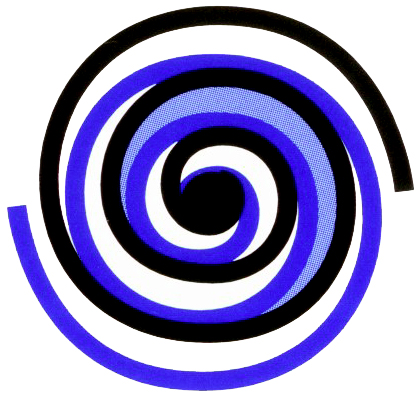

Step 3

As one scroll continue orbiting, the refrigerant is compressed into an increasingly smaller, crescent-shaped pocket.

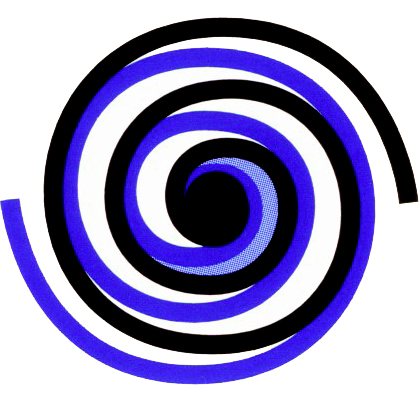

Step 4

By the time the refrigerant reaches a central port in the stationary scroll, it has achieved maximum (discharge) pressure.

Step 5

During actual operation, all passages are in various stages of compression at all times, resulting in near-continuous intake and discharge for optimum performance.

Need Application Assistance?

Our Experienced Team Can Save You Time & Money.

Tell Us About Your Project