Determing the correct style of chiller flow circuit is just as important as matching chilling capacity to a given process.

The following explains the major differences between the two types of flow circuits.

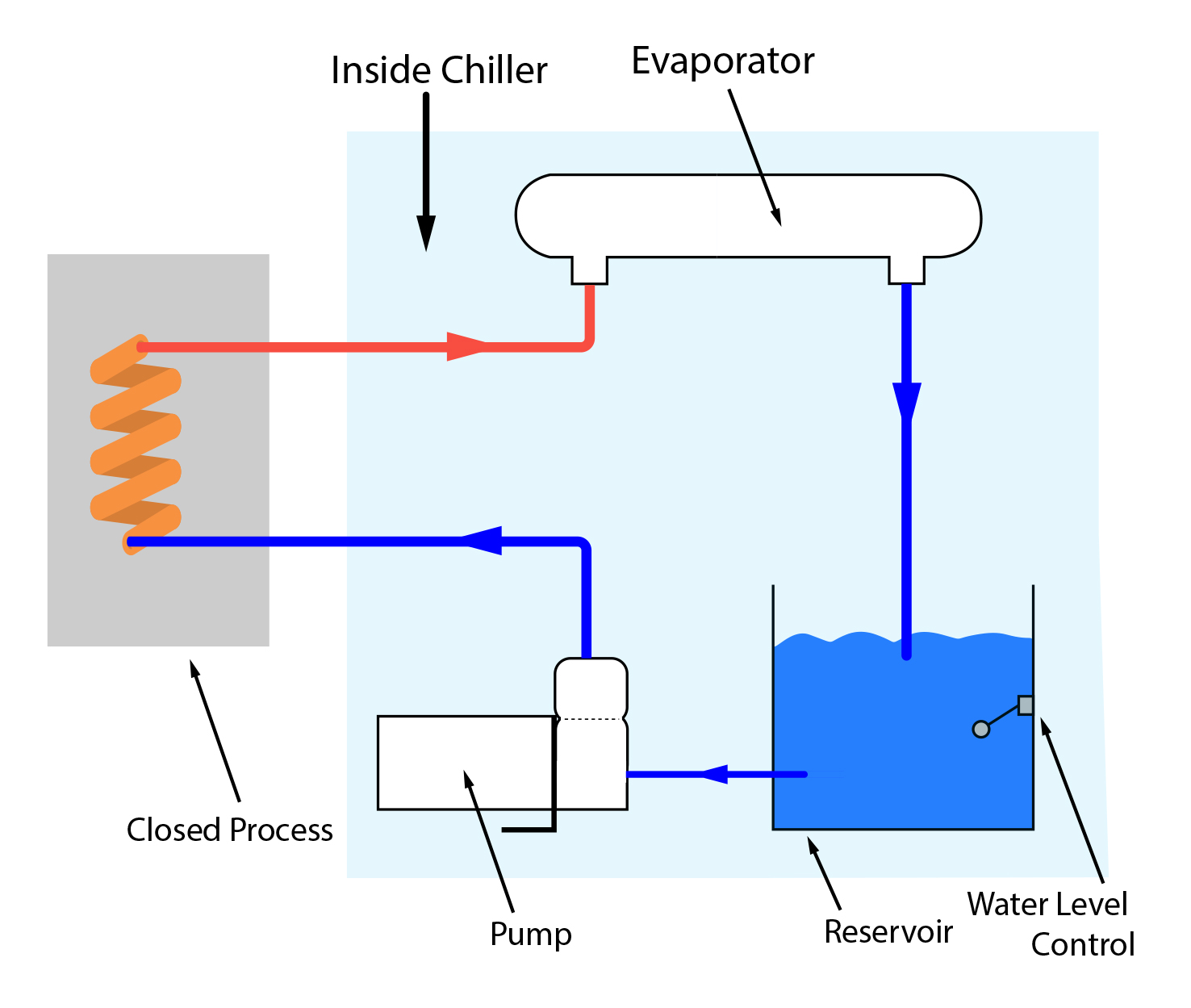

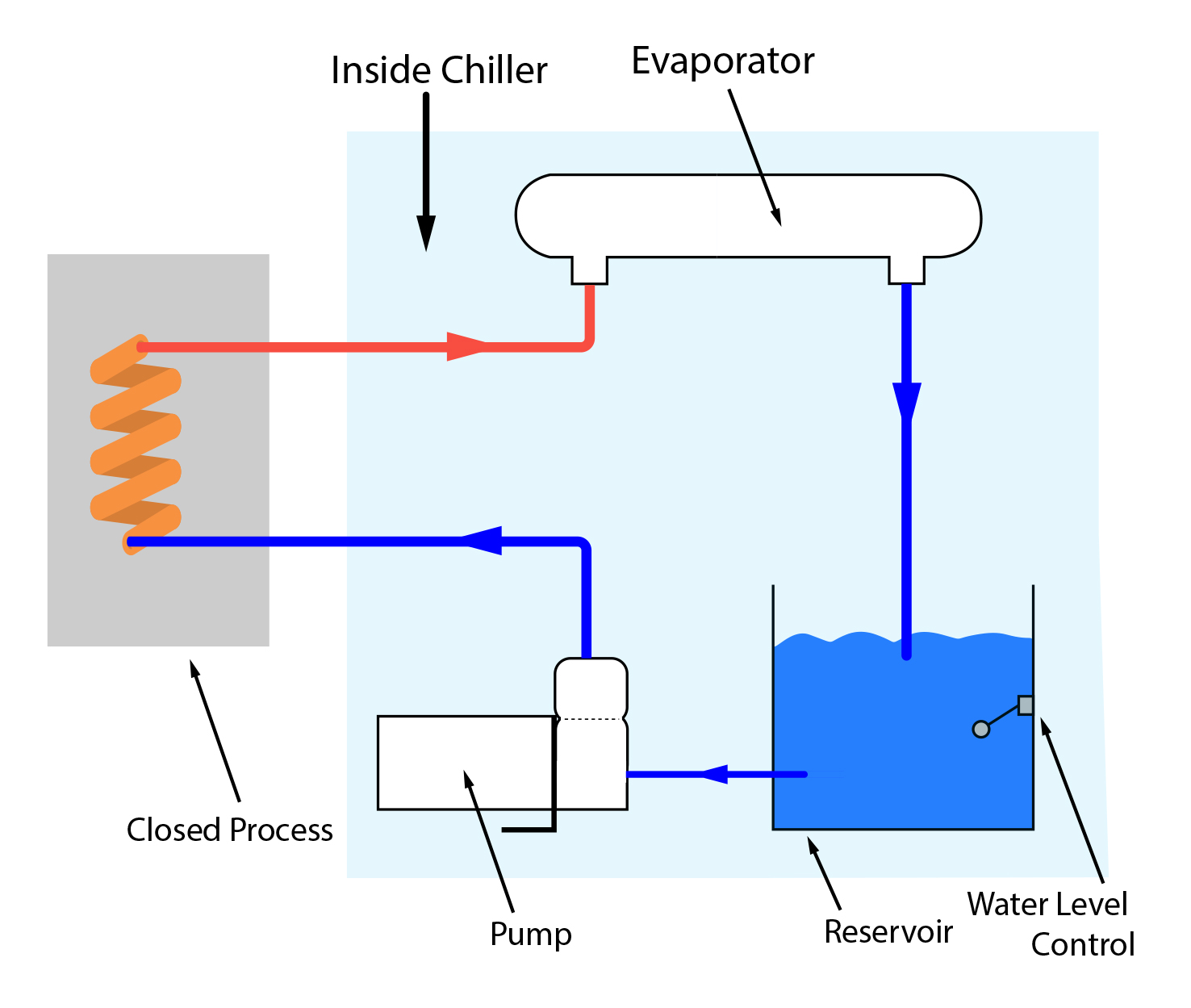

Standard Flow Chillers:

- Advantage standard flow chillers are intended to be used on closed loop processes, such as molds, rolls, dies, coils, etc.

- Water returning to the chiller is dependant on flow generated initially by the chiller process pump.

- If the loop is open to the atmosphere at any point, such as an extrusion trough, overflow will always result.

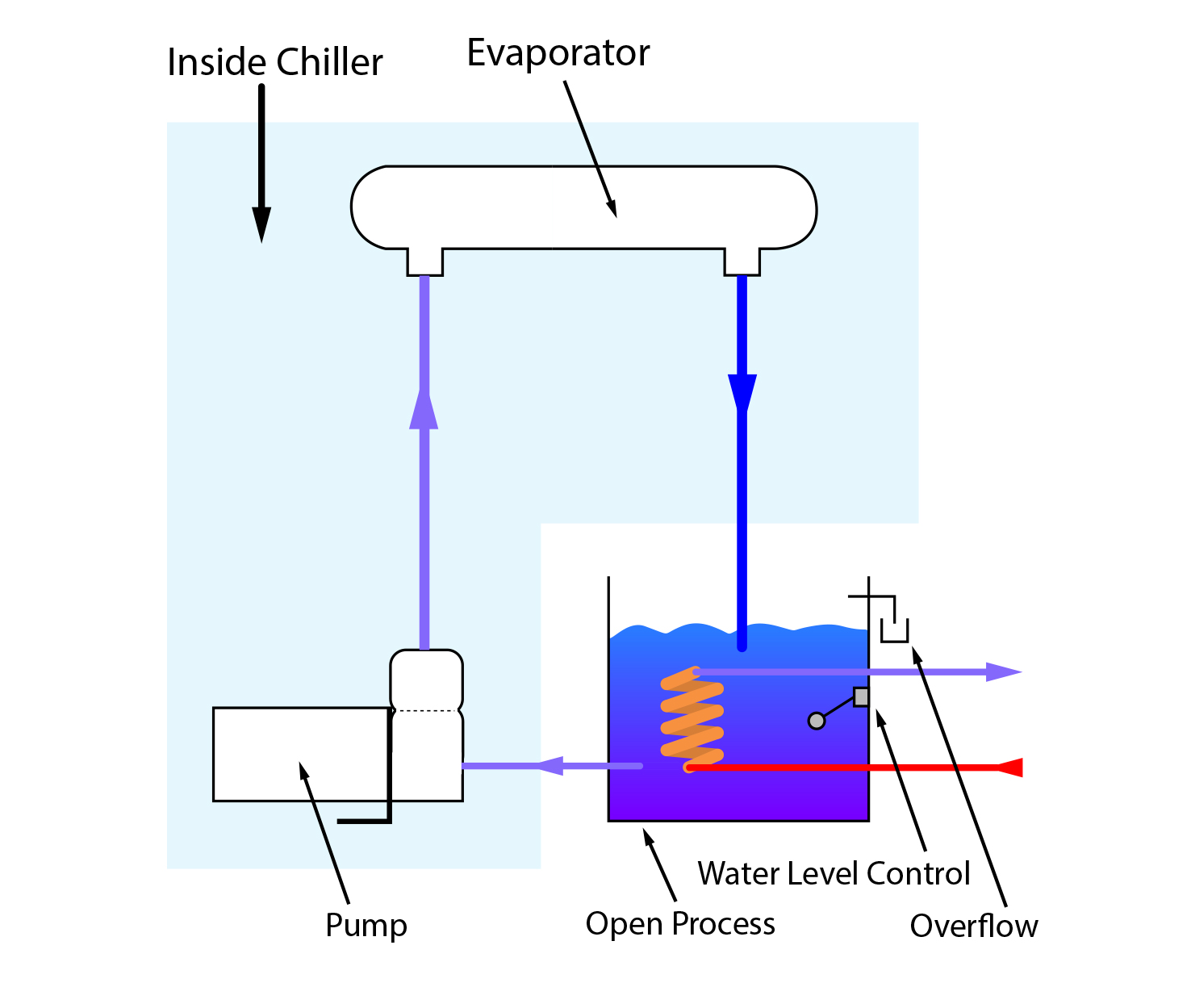

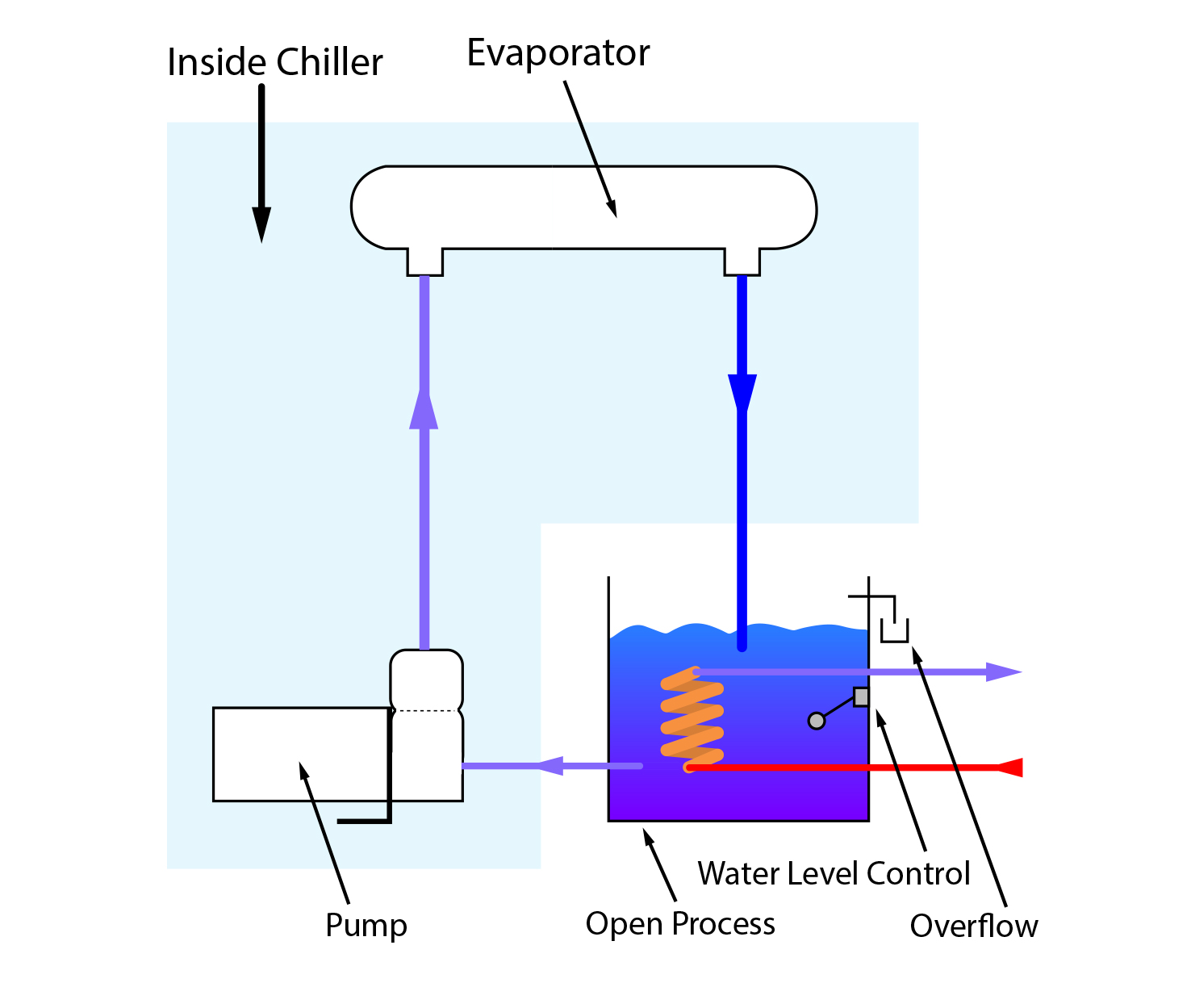

Reverse Flow Chillers:

- Advantage reverse flow chillers are designed specifically for open circuit processes.

- Notice that the flow circui remains basically the same but the process acts as the chiller's reservoir and gravity returns water to the pump suction.

- System water make-up and level control is accomplished externally at the process since the chiller contains no reservoir.

- A reverse flow chiller is identified by an "R" in the model number. For example: MG-10A-R

- Turn on and off individual units.